25 years after we first came on the scene as pioneers in the fiber optic communication market, OCC continues to outperform our competitors. How do we do it? What sets us apart from the rest? How did we build our reputation as a one-source solution for our customers?

While our customers love our innovative products, they value something else even more: reliability and durability.

Reliable, and Durable Products

Cables are the lifeline of the broadcast industry. Things move fast, and industry leaders need to know that their cables will function when it matters most, AND they will stand the test of time. After all, when the average repair runs $325 per cable end, the fewer repairs a cable needs, the more you save.

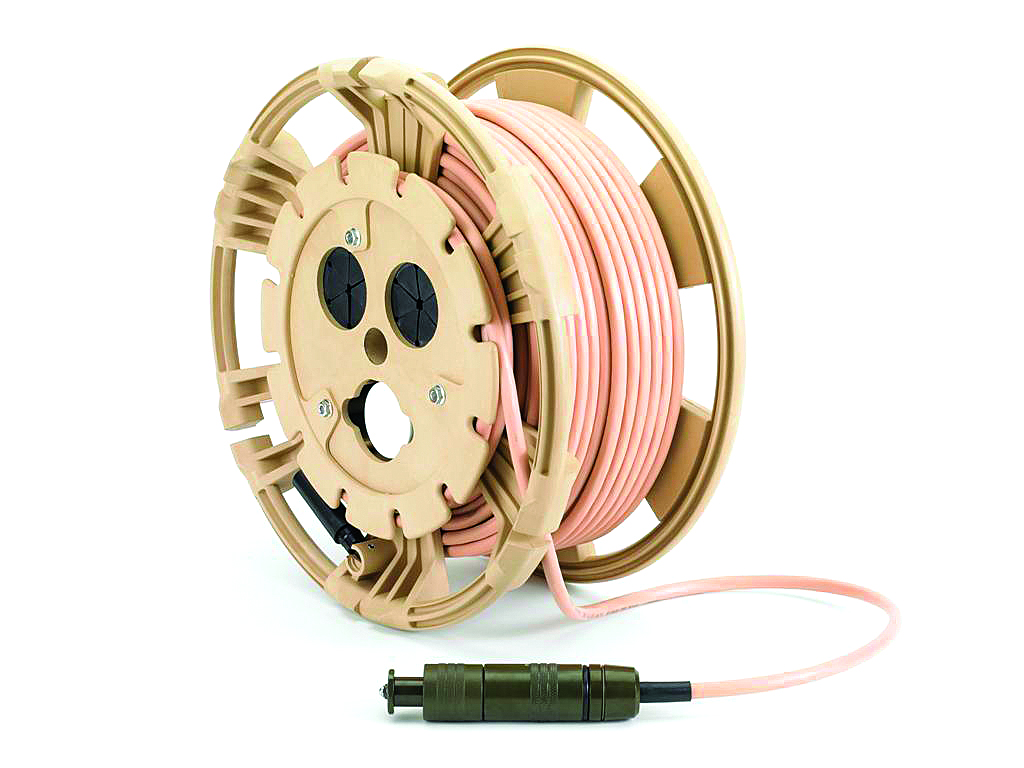

Our SMPTE cables, enclosures, and custom-built assemblies aren’t just state-of-the-art, they are built to last. That’s what makes customers like Jason Friess, Director of Fiber Optic Engineering at the NEP Group, choose OCC SMPTE products. “OCC cables fail less often than their competitor’s products,” says Friess.

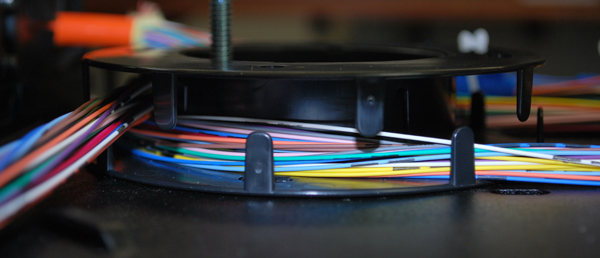

In fact, our product has made a positive impact on the NEP Group’s bottom line. Friess continues, “OCC’s Migration Control Technology has led to a substantial decrease in repair and restoration costs for our company. Because there is little-to-no migration in the copper components of the cable, we see fewer shorts that occur.”

OCC’s Cables Don’t Let You Down

Live events are stressful under the best of circumstances, but when you have dependable products on your side, the potential for mishap decreases. Our SMPTE cable, enclosures, and custom-built assemblies ensure that your broadcast runs seamlessly. The NEP Group consistently uses OCC SMPTE products for their live events across the country. Why? They know that we provide reliable products quickly and consistently with every order.

Friess says, “I can count on OCC to always provide consistent products for NEP. Their cable has zero variation in the jacketing materials, coloring, and finish. I continue to choose OCC because I can count on their products always performing to my expectation.”

Depend On OCC

At OCC, we pride ourselves on our innovation and our expertise. We’ve evolved from our role as forerunners in fiber optic communication to the second largest manufacturer of multimode fiber optic cable for the North American enterprise market. In fact, we’re not just the top choice for companies like NEP, but we’re the premier manufacturer of ground tactical fiber optic cable for the U.S. military and its allies.

Better yet, our technical support and customer service are second to none. Quality is a big deal at OCC. We’ve received many certifications, recognition, and awards from the U.S. Department of Defense, the U.S. Department of Commerce, and the U.S. Patent Office as well as the Commonwealth of Virginia, Start-It Magazine, the Roanoke-Blacksburg Technology Council, and more. OCC is also committed to employing green manufacturing techniques and conscientious of our carbon footprint, too.

If you’re looking for a customized cable solution, let’s talk.

demanding applications including:

demanding applications including: