One of the biggest challenges that colleges and universities face is the ever-increasing demand for bandwidth. With the BYOD mentality that most campuses face today,

the ability to provide easy access to information and to communicate no matter where you are is essential. Campus life no longer dictates reliable Internet service just in the classroom. Now it is required everywhere. As the amount of data and file sizes increase, as well as the need for real-time video and OTA capabilities, the need for increased bandwidth becomes critical. Not to mention the growing need for network and campus security to protect people and property. These increased demands are driving the need for innovative copper and optical fiber cabling technologies that are able to ensure reliable performance and faster data rates.

By implementing a Passive Optical LAN system, higher education facilities can reap the benefits of a streamlined, high-bandwidth network architecture while saving both time and money. Universities cannot afford the downtime associated with rewiring in order to provide greater bandwidth to their students. Passive Optical LAN systems utilize single-mode fiber optic cable. Single-mode fiber optic cable provides the greatest bandwidth compared to any other communications medium available on the market today. At a very economical cost compared to a traditional network infrastructure, Passive Optical LANs minimize the need for future cabling upgrades.

Not only can Passive Optical LANs support telephone, data and video services but they can also service security, building automation systems and wireless services. Other structured cabling solutions necessitate more cables and/or electronics to support the services now required on a modern campus. The added savings of not having to install the necessary plethora of cables to support these additional electronics, shows that Passive Optical LANs are a much more inexpensive solution (both in capital and operational costs), saving the college both up front and year over year costs. And because of the utilization of single-mode fiber, they can expect their investment to payoff for years to come.

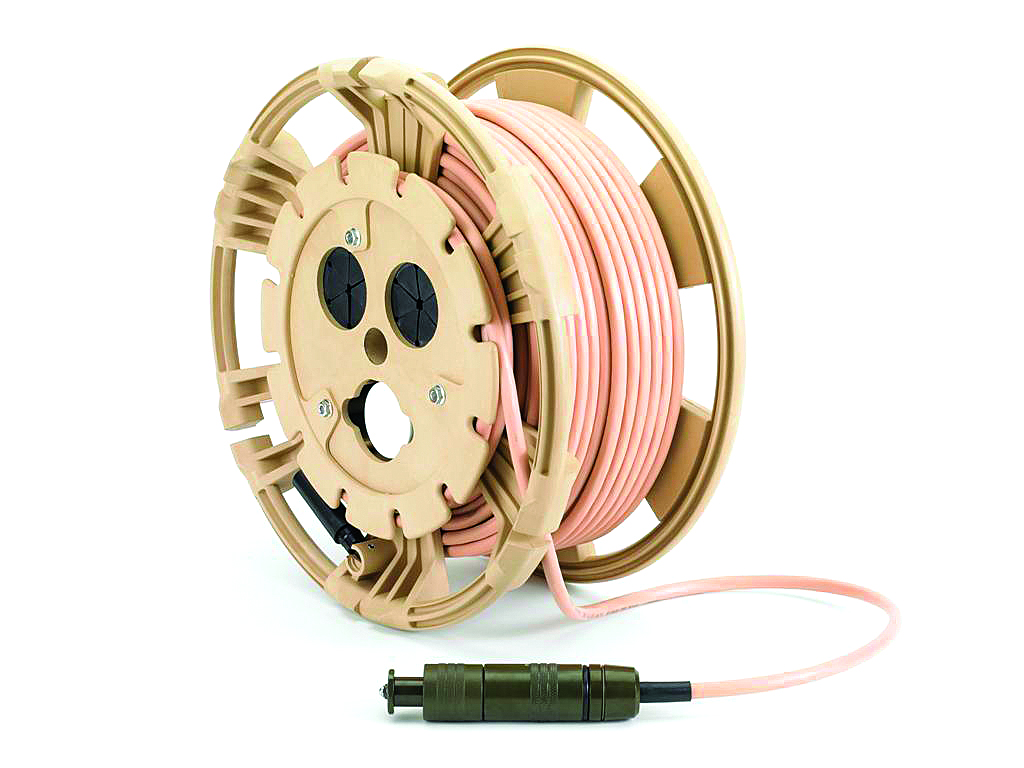

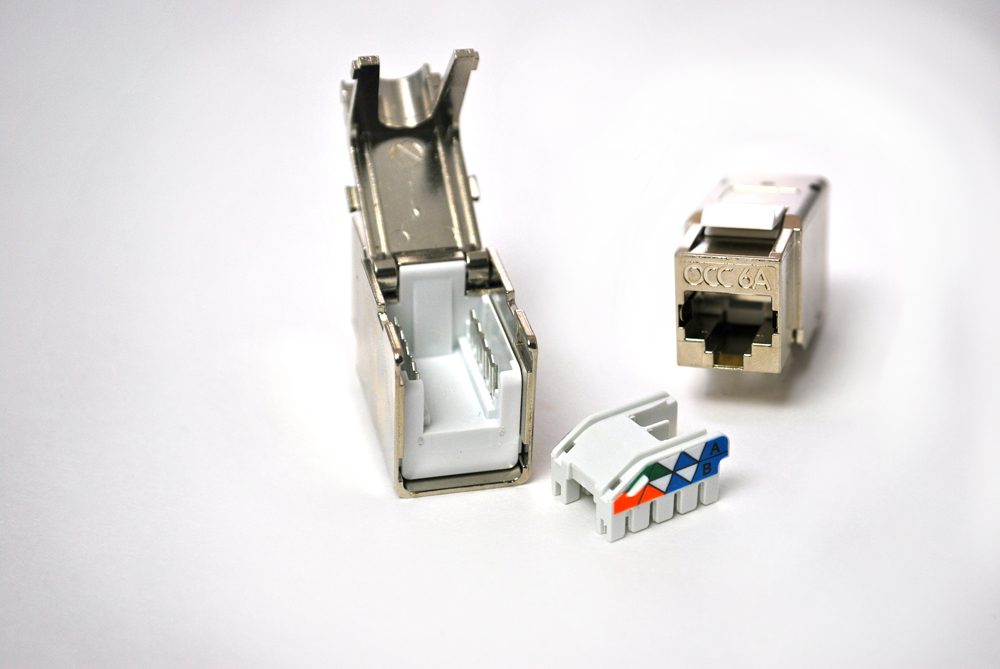

OCC’s newly developed Passive Optical LAN takes all those benefits and amplifies them to provide a reliable system that allows for effortless installations. Easy to install and manage, OCC’s POL offers a versatile system that affords substantial improvements in overall CAPEX and OPEX savings as well as streamlines current and future upgrades.

To learn more about OCC’s Passive Optical LAN system, watch this short 2 minute video on all the unique benefits POL has to offer: Click here.

On May 27, 2014, Optical Cable Corporation (OCC) was one of 66 companies selected as a winner of the “E” award.

On May 27, 2014, Optical Cable Corporation (OCC) was one of 66 companies selected as a winner of the “E” award.

demanding applications including:

demanding applications including: