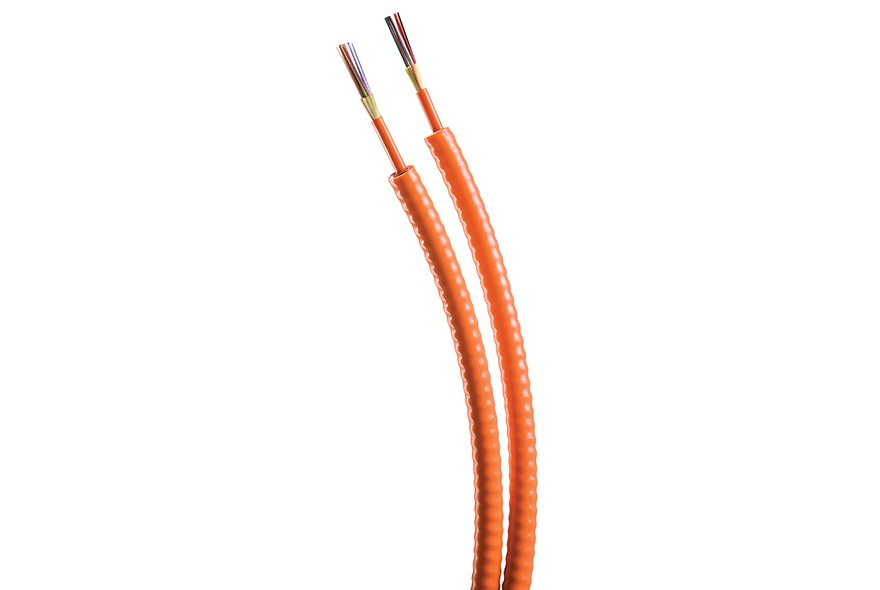

B-Series Breakout – Riser Rated Tray Cables

Installation zone RECOMMENDATION1

1

1

1

- Ideal for installations requiring an extremely rugged and reliable cable design where maximum mechanical and environmental protection are necessary

- Typical industrial uses are factory automation, power generation and other utilities, oil and gas refining, and surface mining

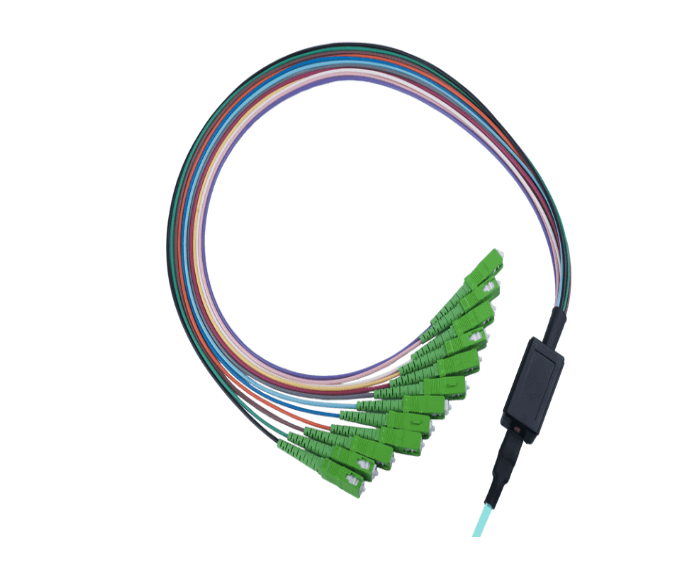

- Easiest cable to install where direct termination of the subcable to a connector and a direct run to panels and equipment are desired

- Ideal for locations requiring low-temperature performance along with a flame rating

Features

- Fiber Optic tray Cable: Suitable for use in cable trays

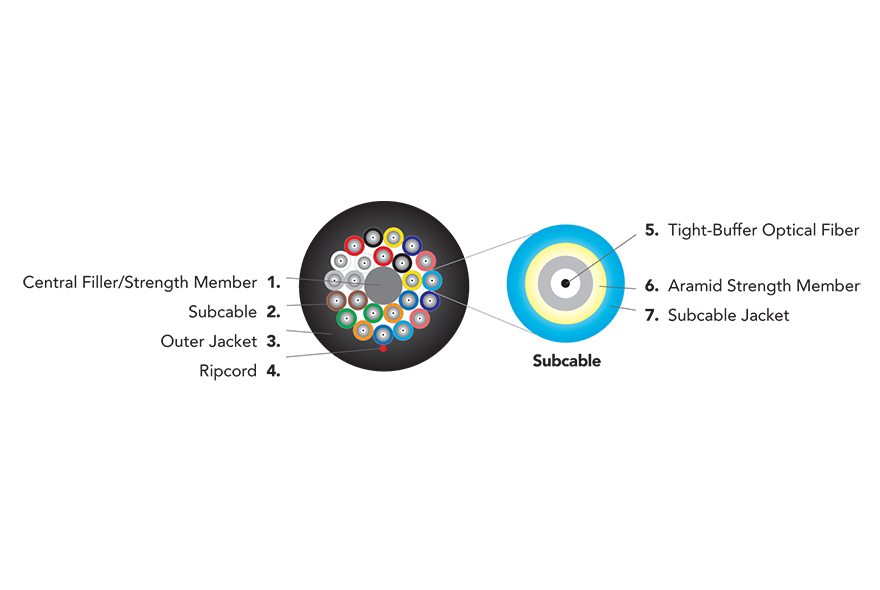

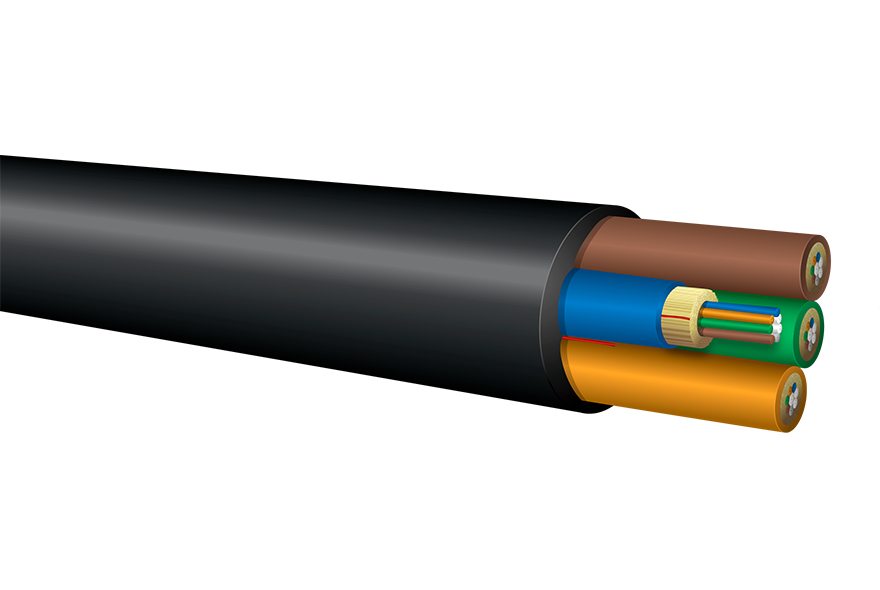

- Individual fibers and strength members protected in a subcable configuration

- Most rugged cable design with individual subcables for routing to diverse intelligent devices with direct connector termination at each device

- Meets all applicable standards for Impact & Crush Resistance (CSA C22.2 No. 230)

- Fibers may be directly terminated at factory devices or central locations using connectors with no further protection required

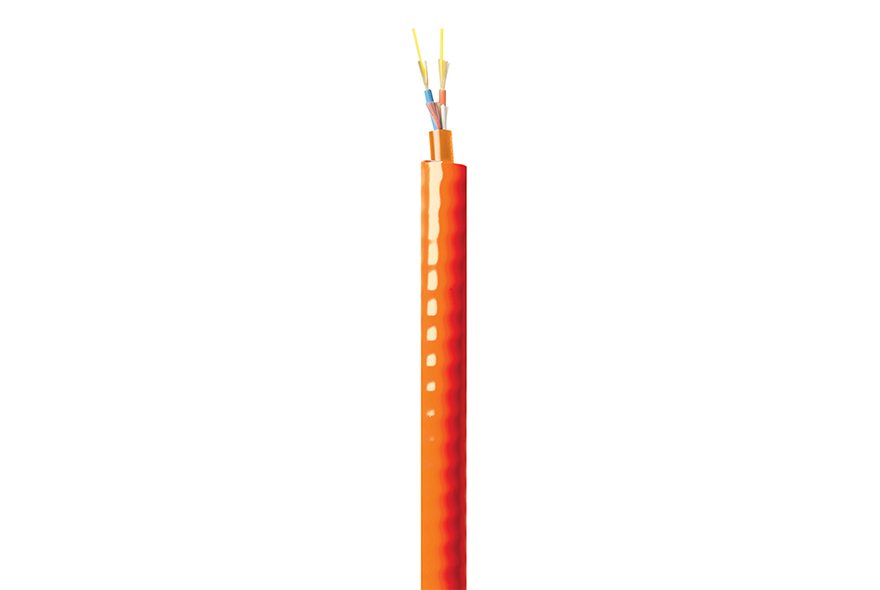

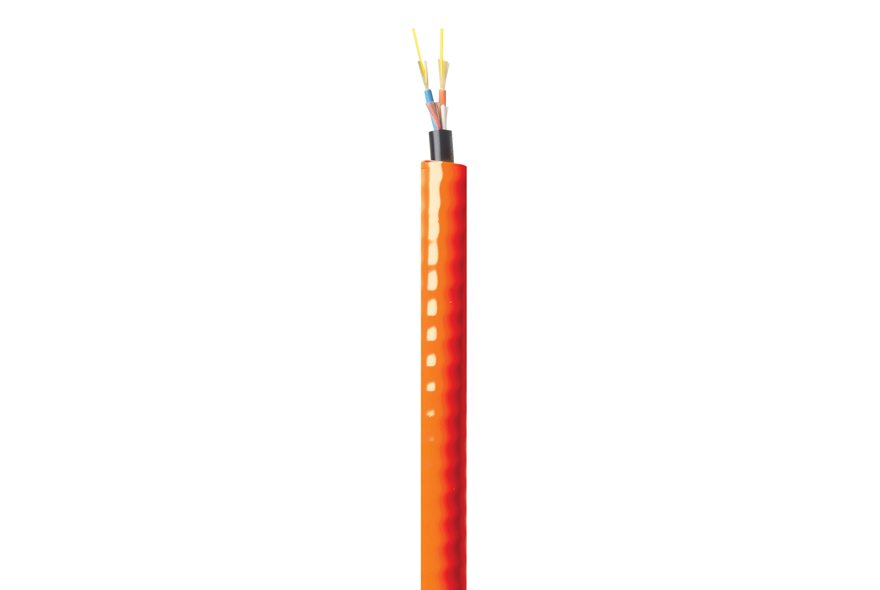

- J-Jacket is UV, fungus and moisture resistant

- Designed for indoor/outdoor installations, including cable trays

- 2 to 72 fiber counts are available with 2.0mm or 2.5mm subcables

- Low-temperature PVC outer jacket (J-Jacket) provides excellent performance and flexibility at low temperatures

- Wide operating temperature range of -50°C to +75°C

- Core-locked™ jacket prevents cable from flattening and the jacket from wrinkling in tight bends:

- Permits pulling with direct attachment of wire mesh grip; not need to access inner aramid strength members

- Improved crush and tear resistance

- Contains 25% more material than conventional jackets

- High crush and tensile load ratings compared to similar tray service fiber optic cables

- Oil resistant for use in industrial applications (J-Jacket)

- UL listed in accordance with NEC section 770.179(b) for use in vertical runs in building riser shafts or from floor to floor

- Designed to exceed the flammability requirements of Chapter 8 of IEEE 383

Characteristics

| Characteristic | PVC Outer Jacket | Low-Temperature PVC Outer Jacket | Indoor/Outdoor Zero Halogen Outer Jacket |

|---|---|---|---|

| Operating Temp | -40°C to +85°C | -50°C to +75°C | -40°C to +70°C |

| Storage Temp | -55°C to +85°C | -55°C to +85°C | -40°C to +85°C |

| Install Temp | -10°C to +60°C | -30°C to +60°C | -20°C to +60°C |

| Flame Retardancy | UL listed type OFNR (UL 1666) and FT4 (CSA C22.2 No. 232) | UL listed type OFNR (UL 1666) and FT4 (CSA C22.2 No. 232) | UL listed type OFNR (UL 1666) and FT4 (CSA C22.2 No. 232) |

| Crush Resist | 2200 N/cm | 2200 N/cm | 2200 N/cm |

| Impact Resist | 1500 impacts | 1500 impacts | 1500 impacts |

| Flex Resist | 2000 cycles | 2000 cycles | 2000 cycles |

| Jacket Type | D | J | Z |

* 2.0mm Subcables = BE; 2.5mm Subcables = BX

Standards

OCC Indoor/Outdoor tight-buffered fiber optic cables meet the functional requirements of the following standards:

- UL 1666

- CSA C22.2 No. 232

- CSA C22.2 No. 230

- GR-409-CORE

- ICEA-S-104-696

- ICEA-S-83-596

- TIA-568

- TIA-598

Specifications

with 2.5mm subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Spec Sheet | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | BX002J***9KR | Download Spec Sheet |

7.0 (0.28) |

41.0 (28.0) |

1,200 (270) |

500 (110) |

10.5 (4.1) |

7.0 (2.8) |

|

| 4 | BX004J***9KR | Download Spec Sheet |

8.3 (0.33) |

68.0 (46.0) |

2,000 (450) |

800 (180) |

12.5 (4.9) |

8.3 (3.3) |

|

| 6 | BX006J***9KR | Download Spec Sheet |

9.6 (0.38) |

88.0 (59.0) |

3,000 (670) |

1,200 (270) |

14.4 (5.7) |

9.6 (3.8) |

|

| 8 | BX008J***9KR | Download Spec Sheet |

11.6 (0.46) |

133.0 (89.0) |

4,000 (900) |

1,700 (380) |

17.4 (6.9) |

11.6 (4.6) |

|

| 12 | BX012J***9KR | Download Spec Sheet |

14.1 (0.56) |

159.0 (107.0) |

6,000 (1,350) |

2,500 (560) |

21.2 (8.3) |

14.1 (5.6) |

|

| 18 | BX018J***9KR | Download Spec Sheet |

15.3 (0.60) |

226.0 (152.0) |

8,000 (1,800) |

3,500 (790) |

23.0 (9.1) |

15.3 (6.0) |

|

| 24 | BX024J***9KR | Download Spec Sheet |

17.6 (0.69) |

292.0 (196.0) |

10,000 (2,250) |

3,800 (850) |

26.4 (10.4) |

17.6 (6.9) |

|

| 36 | BX036J***9KR | Download Spec Sheet |

20.9 (0.82) |

375.0 (252.0) |

14,000 (3,150) |

6,000 (1,350) |

31.4 (12.4) |

20.9 (8.2) |

|

| 48 | BX048J***9KR | Download Spec Sheet |

24.2 (0.95) |

501.0 (336.0) |

18,000 (4,050) |

7,500 (1,690) |

36.3 (14.3) |

24.2 (9.5) |

|

| 60 | BX060J***9KR | Download Spec Sheet |

26.4 (1.04) |

604.0 (406.0) |

22,000 (4,950) |

8,800 (1,980) |

39.6 (15.6) |

26.4 (10.4) |

|

| 72 | BX072J***9KR | Download Spec Sheet |

28.9 (1.14) |

768.0 (516.0) |

26,000 (5,845) |

11,000 (2,470) |

43.4 (17.1) |

28.9 (11.4) |

|

with 2.0mm subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Spec Sheet | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | BE002J***9KR | Download Spec Sheet |

6.0 (0.24) |

40.0 (27.0) |

800 (180) |

200 (40) |

9.0 (3.5) |

6.0 (2.4) |

|

| 4 | BE004J***9KR | Download Spec Sheet |

6.9 (0.27) |

52.0 (35.0) |

1,600 (360) |

400 (90) |

10.4 (4.1) |

6.9 (2.7) |

|

| 6 | BE006J***9KR | Download Spec Sheet |

8.1 (0.32) |

67.0 (45.0) |

2,400 (560) |

600 (130) |

12.2 (4.8) |

8.1 (3.2) |

|

| 8 | BE008J***9KR | Download Spec Sheet |

9.4 (0.37) |

88.0 (59.0) |

3,200 (720) |

800 (180) |

14.1 (5.6) |

9.4 (3.7) |

|

| 12 | BE012J***9KR | Download Spec Sheet |

10.9 (0.43) |

108.0 (73.0) |

4,800 (1,000) |

1,200 (270) |

16.4 (6.5) |

10.9 (4.3) |

|

| 18 | BE018J***9KR | Download Spec Sheet |

12.6 (0.50) |

156.0 (105.0) |

6,000 (1,350) |

1,500 (340) |

18.9 (7.4) |

12.6 (5.0) |

|

| 24 | BE024J***9KR | Download Spec Sheet |

14.7 (0.58) |

218.0 (146.0) |

7,200 (1,600) |

1,800 (400) |

22.1 (8.7) |

14.7 (5.8) |

|

| 36 | BE036J***9KR | Download Spec Sheet |

16.8 (0.66) |

266.0 (179.0) |

9,600 (2,100) |

2,400 (540) |

25.2 (9.9) |

16.8 (6.6) |

|

| 48 | BE048J***9KR | Download Spec Sheet |

20.1 (0.79) |

387.0 (260.0) |

12,000 (2,700) |

3,000 (680) |

30.1 (11.9) |

20.1 (7.9) |

|

| 60 | BE060J***9KR | Download Spec Sheet |

16.8 (0.66) |

299.0 (201.0) |

15,000 (3,400) |

3,750 (850) |

25.2 (9.9) |

16.8 (6.6) |

|

| 72 | BE072J***9KR | Download Spec Sheet |

26.0 (1.02) |

652.0 (438.0) |

16,800 (3,800) |

4,200 (900) |

39.0 (15.4) |

26.0 (10.2) |

|

Instruction Sheets

Related Documents

Please Login Here to access additional documents.

More Industrial Cables