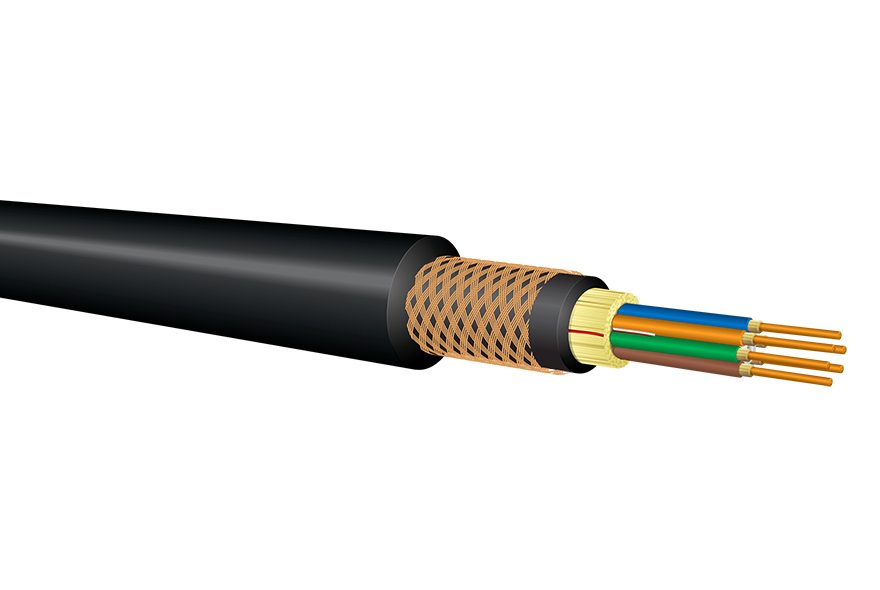

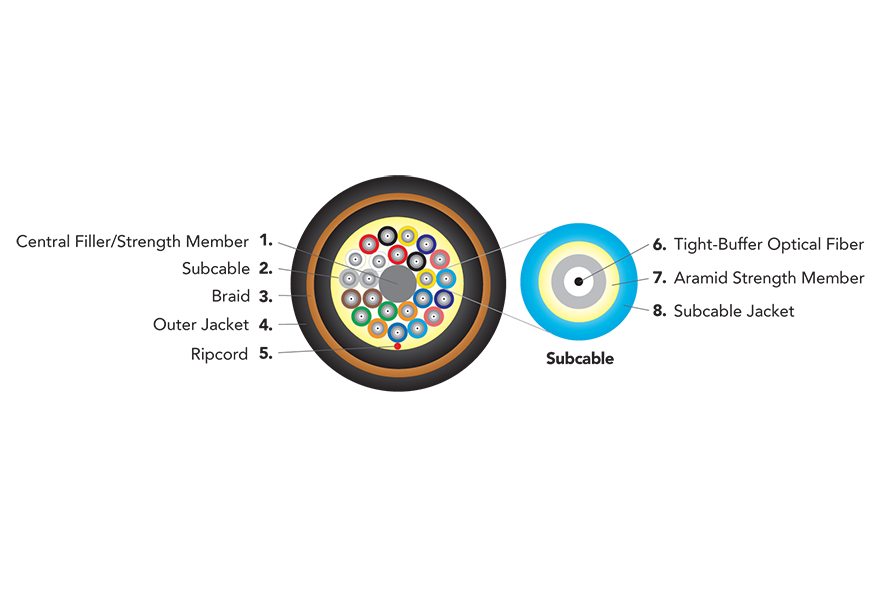

B-Series Breakout – LSZH Braided-Armor ABS-Approved Cables

Installation zone RECOMMENDATION1

1

1

1

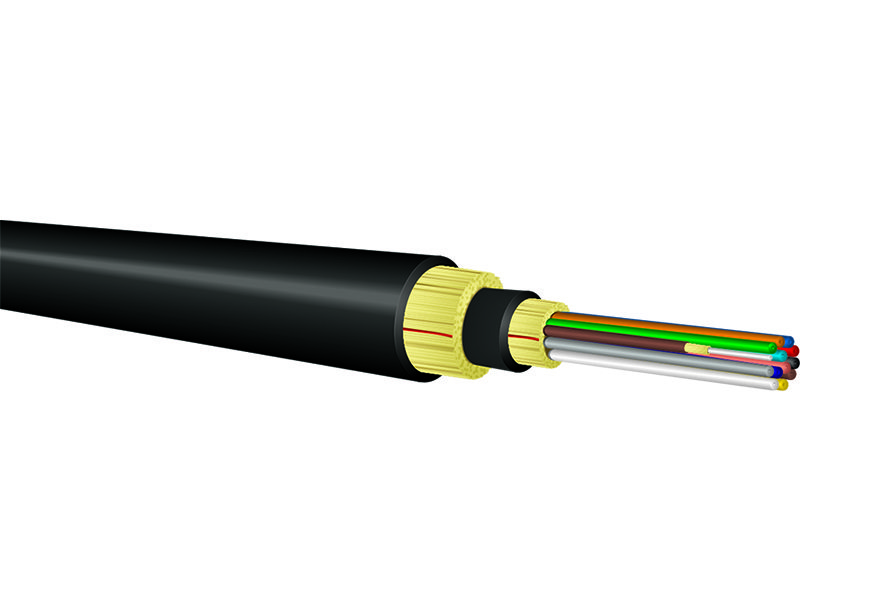

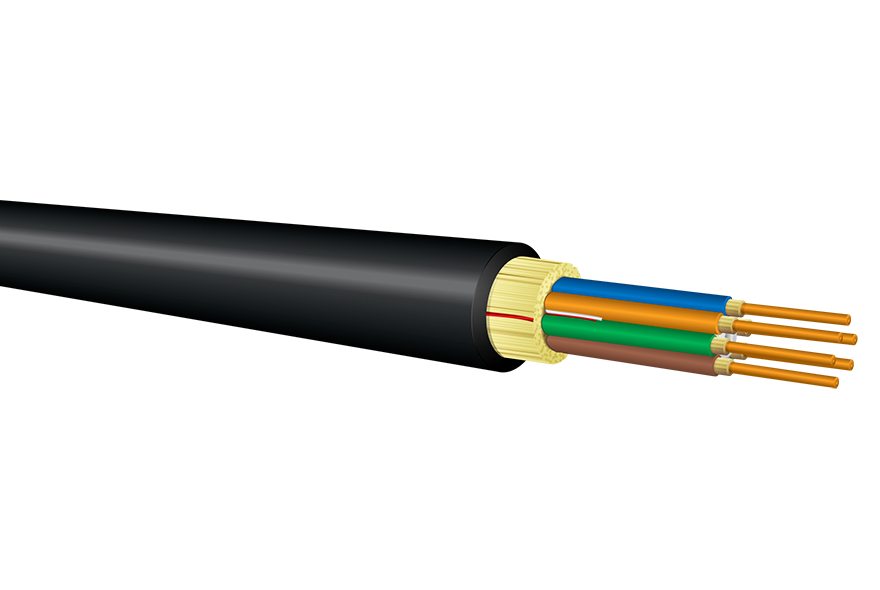

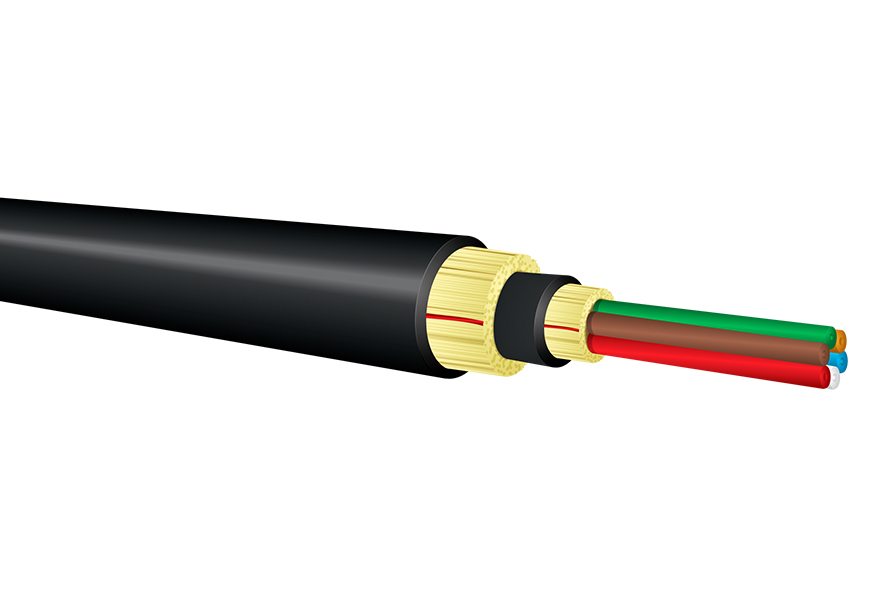

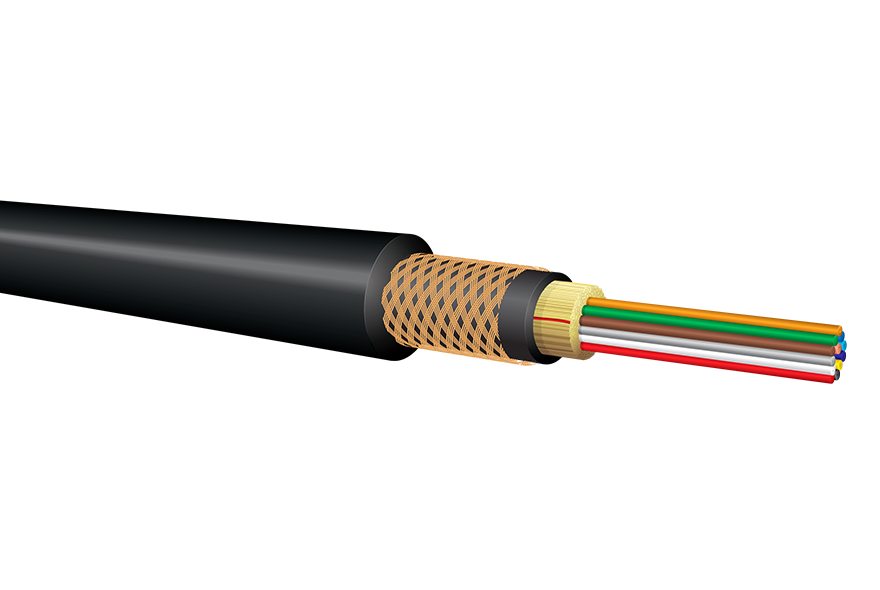

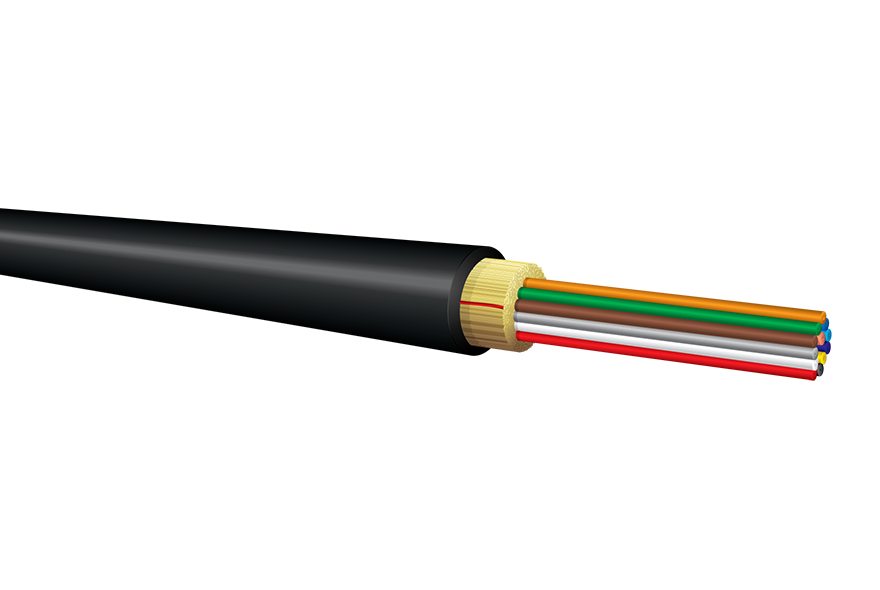

- Marine and offshore tight-buffered cable design for use in installations requiring a flame-retardant, low-smoke, and zero-halogen cable incorporating individual subcables for direct termination

Applications

- Marine and offshore tight-buffered cable design for use in installations requiring a flame-retardant, low-smoke, and zero-halogen cable incorporating individual subcables for direct termination

Features

- Zero-halogen construction meets IEC 60754-2

- Meets low-smoke requirements of UL 1685

- UL listed OFCR-ST1

- ABS-approved for 2022 Steel Vessels Rules 1-1-4/7.7.1-1- Appendix 3 1-1- Appendix 4, 4-8-3/9.1, 4-8-3/9.5 (I & II), 4-8-3/9.13

- ABS-approved for 2022 Mobile Offshore Drilling Units (MODU) Rules 1-1-4/7.7, 1-1-Appendix 2, 1-1-Appendix 3, 4-3-4/7.1.1, 7.1.2, 7.1.6

- Bronze braid armor adds a degree of durability to limit damage due to abrasion

- Suitable for indoor or outdoor applications

- Jacket is UV, fungus, and moisture resistant

- Round cable construction for easy handling and termination

- Includes ripcord for easy outer jacket removal

- Rugged breakout-style cable for deck applications with 2-24 fibers

- Optical fiber types include 62.5/125, 50/125, and single-mode

- Available with 500µm primary acrylate-coated fiber for maximum mechanical and environmental protection of the optical fiber

- Braid layer applied per IEEE 1580

- 2.0mm and 2.5mm subcables available

Characteristics

| Characteristic | 2.0mm subcables | 2.5mm subcables |

|---|---|---|

| Operating Temp | -40°C to +70°C | -40°C to +70°C |

| Storage Temp | -40°C to +70°C | -40°C to +70°C |

| Install Temp | -20°C to +70°C | -20°C to +70°C |

| Flame Retardancy | Type approved 22-2208523-PDA | Type approved 22-2208523-PDA |

| Crush Resist | 2200 N/cm | 2200 N/cm |

| Impact Resist | 1500 impacts | 1500 impacts |

| Jacket Type | Z | Z |

Standards

OCC B-Series Breakout Low-Smoke Zero-Halogen braided armor ABS-approved cables meet the functional requirements of the following standards:

- IED 60754-2

- UL 1666 OFCR

- UL 1685 OFCR-ST1

- MIL-C-24643

- ICEA-S-104-696

- TIA-568

- TIA-598

Specifications

2.0mm Subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | BE002Z***9KRB2-*ABS |

12.0 (0.47) |

198.0 (133.0) |

1,600 (360) |

400 (90) |

18.0 (7.1) |

12.0 (4.7) |

||

| 4 | BE004Z***9KRB2-*ABS |

12.0 (0.47) |

198.0 (133.0) |

1,600 (360) |

400 (90) |

18.0 (7.1) |

12.0 (4.7) |

||

| 6 | BE006Z***9KRB2-*ABS |

13.0 (0.51) |

233.0 (157.0) |

2,400 (540) |

600 (130) |

19.5 (7.7) |

13.0 (5.1) |

||

| 8 | BE008Z***9KRB2-*ABS |

14.3 (0.56) |

278.0 (187.0) |

3,200 (720) |

800 (180) |

21.5 (8.5) |

14.3 (5.6) |

||

| 12 | BE012Z***9KRB2-*ABS |

15.5 (0.61) |

319.0 (214.0) |

4,800 (1,800) |

1,200 (270) |

23.3 (9.2) |

15.5 (6.1) |

||

| 18 | BE018Z***9KRB2-*ABS |

16.7 (0.66) |

368.0 (247.0) |

7,200 (1,620) |

1,800 (400) |

25.1 (9.9) |

16.7 (6.6) |

||

| 24 | BE024Z***9KRB2-*ABS |

18.9 (0.74) |

454.0 (305.0) |

9,600 (2,100) |

2,400 (540) |

28.3 (11.1) |

18.9 (7.4) |

||

2.5mm Subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | BX002Z***9KRB2-*ABS |

13.2 (0.52) |

238.0 (160.0) |

2,000 (450) |

800 (180) |

19.8 (7.8) |

13.2 (5.2) |

||

| 4 | BX004Z***9KRB2-*ABS |

13.2 (0.52) |

238.0 (160.0) |

2,000 (450) |

800 (180) |

19.8 (7.8) |

13.2 (5.2) |

||

| 6 | BX006Z***9KRB2-*ABS |

14.5 (0.57) |

280.0 (188.0) |

3,000 (670) |

1,200 (270) |

21.8 (8.6) |

14.5 (5.7) |

||

| 8 | BX008Z***9KRB2-*ABS |

16.3 (0.64) |

344.0 (231.0) |

4,000 (900) |

1,700 (3,800) |

24.5 (9.6) |

16.3 (6.4) |

||

| 12 | BX012Z***9KRB2-*ABS |

17.9 (0.70) |

400.0 (269.0) |

6,000 (1,350) |

2,500 (560) |

26.9 (10.6) |

17.9 (7.0) |

||

| 18 | BX018Z***9KRB2-*ABS |

19.8 (0.78) |

477.0 (321.0) |

8,000 (1,800) |

3,500 (790) |

29.7 (11.7) |

19.8 (7.8) |

||

| 24 | BX024Z***9KRB2-*ABS |

21.8 (0.86) |

572.0 (384.0) |

10,000 (2,250) |

3,800 (850) |

32.7 (12.9) |

21.8 (8.6) |

||

Instruction Sheets

Related Documents

- Catalog- Downloadable (PDF)

- Catalog- Interactive

- Laser Ultra-Fox Fiber Performance Chart

- Oil & Gas Solutions Product Guide

Please Login Here to access additional documents.

More Shipboard Cables