DX-Series Distribution – Field Broadcast Cables

Installation zone RECOMMENDATION1

1

1

1

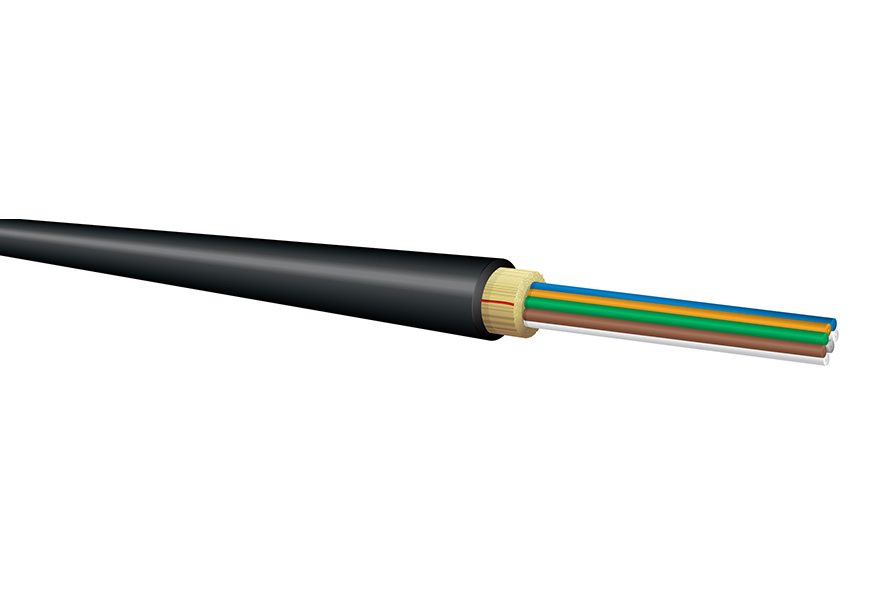

- Deployable cable that is ideal for use in harsh environments where deployment and retrieval for reuse are required

Applications

- Deployable cable that is ideal for use in harsh environments where deployment and retrieval for reuse are required

Features

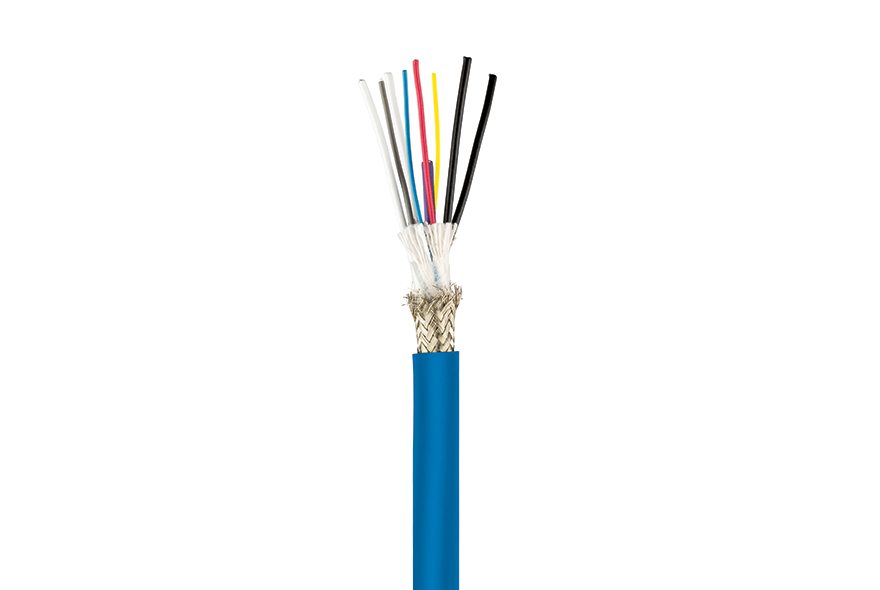

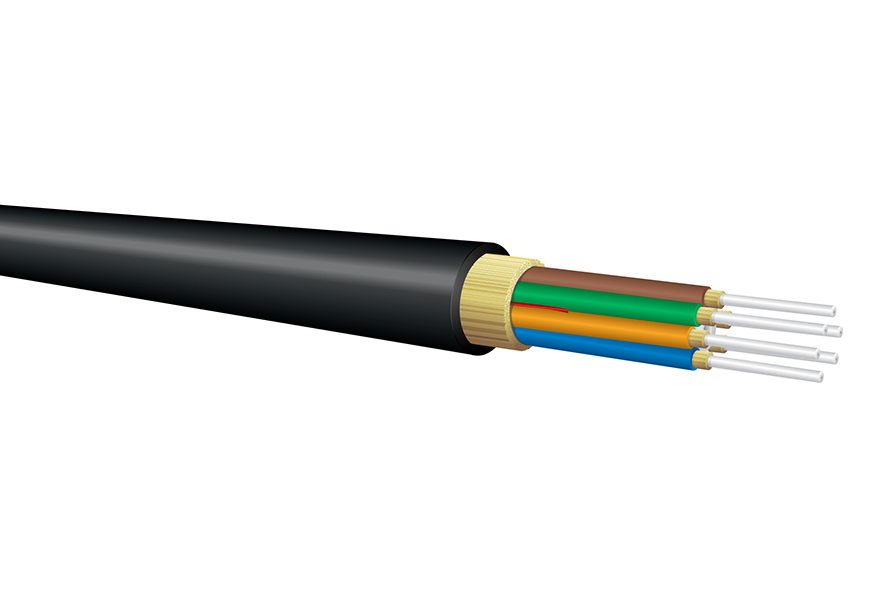

- Extremely strong, lightweight, rugged, survivable tight-buffered cables are designed for broadcast field use and commercial applications

- Compact, round cable design for ease of transportation and deployment

- Core-locked jacket for improved mechanical performance

- Designed for use in adverse environments where reduced size and weight are important

- Helically stranded cable core for flexibility, survival in difficult pulls, and exceptional mechanical protection for the optical fibers

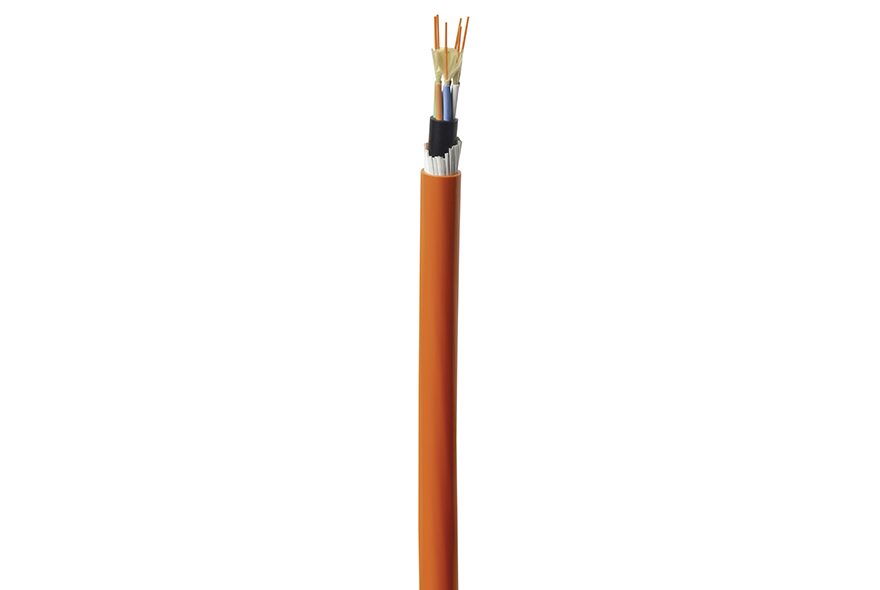

- Cables have been tested and are in use in broadcast data communications applications worldwide

- Can be used outdoors for temporary deployment directly on the ground in all terrains, including severe environments

- Suitable for industrial, mining and petrochemical environments; chemical resistant

- Crush resistant and resilient with a thick layer of aramid strength members

- Polyurethane jacketed for abrasion, cut and chemical resistance

- Most commonly used with ruggedized multiway military tactical field connectors, for maximum connector retention (400lbs.)

- Tactical Polyurethane (C) outer jacket materials is standard; Flame-Retardant Tactical (V) and Low-Smoke Zero-Halogen (G) outer jacket materials are available

OCC PROVIDED OPTIONS

- Broadcast cables pre-spooled on deployable reels for a ready-to-use product

- Broadcast cables can be pre-terminated with single-fiber or ruggedized multichannel connectors upon request

Characteristics

| Characteristic | C Jacket | G Jacket | V Jacket |

|---|---|---|---|

| Operating Temp | -40°C to +85°C | -40°C to +85°C | -40°C to +85°C |

| Storage Temp | -70°C to +85°C | -70°C to +85°C | -70°C to +85°C |

| Crush Resist | 1800 N/cm | 1800 N/cm | 1800 N/cm |

| Impact Resist | 1500 impacts | 1500 impacts | 1500 impacts |

| Flex Resist | 2000 cycles | 2000 cycles | 2000 cycles |

| Jacket Type | C | G | V |

Specifications

C Jacket

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | DX002C***9KB |

5.0 (0.20) |

21.0 (14.0) |

1,800 (400) |

600 (130) |

5.0 (2.0) |

2.5 (1.0) |

||

| 4 | DX004C***9KB |

5.5 (0.22) |

27.0 (18.0) |

1,800 (400) |

600 (130) |

5.5 (2.2) |

2.8 (1.1) |

||

| 6 | DX006C***9KB |

6.0 (0.24) |

32.0 (22.0) |

1,800 (400) |

600 (130) |

6.0 (2.4) |

3.0 (1.2) |

||

| 8 | DX008C***9KB |

6.5 (0.26) |

37.0 (25.0) |

1,800 (400) |

600 (130) |

6.5 (2.6) |

3.3 (1.3) |

||

| 10 | DX010C***9KB |

6.5 (0.26) |

38.0 (26.0) |

2,100 (470) |

700 (160) |

6.5 (2.6) |

3.3 (1.3) |

||

| 12 | DX012C***9KB |

6.5 (0.26) |

41.0 (28.0) |

2,100 (470) |

700 (160) |

6.5 (2.6) |

3.3 (1.3) |

||

| 18 | DX018C***9KB |

7.5 (0.30) |

48.0 (32.0) |

2,400 (540) |

800 (180) |

7.5 (3.0) |

3.8 (1.5) |

||

| 24 | DX024C***9KB |

8.5 (0.33) |

60.0 (40.0) |

3,000 (670) |

1,000 (220) |

8.5 (3.3) |

4.3 (1.7) |

||

G Jacket

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | DX002G***9KB |

5.0 (0.20) |

22.0 (15.0) |

1,800 (400) |

600 (130) |

5.0 (2.0) |

2.5 (1.0) |

||

| 4 | DX004G***9KB |

5.5 (0.22) |

28.0 (19.0) |

1,800 (400) |

600 (130) |

5.5 (2.2) |

2.8 (1.1) |

||

| 6 | DX006G***9KB |

6.0 (0.24) |

33.0 (22.0) |

1,800 (400) |

600 (130) |

6.0 (2.4) |

3.0 (1.2) |

||

| 8 | DX008G***9KB |

6.5 (0.26) |

38.0 (26.0) |

1,800 (400) |

600 (130) |

6.5 (2.6) |

3.3 (1.3) |

||

| 10 | DX010G***9KB |

6.5 (0.26) |

39.0 (26.0) |

2,100 (470) |

700 (160) |

6.5 (2.6) |

3.3 (1.3) |

||

| 12 | DX012G***9KB |

6.5 (0.26) |

42.0 (28.0) |

2,100 (470) |

700 (160) |

6.5 (2.6) |

3.3 (1.3) |

||

| 18 | DX018G***9KB |

7.5 (0.30) |

49.0 (33.0) |

2,400 (540) |

800 (180) |

7.5 (3.0) |

3.8 (1.5) |

||

| 24 | DX024G***9KB |

8.5 (0.33) |

62.0 (42.0) |

3,000 (670) |

1,000 (220) |

8.5 (3.3) |

4.3 (1.7) |

||

V Jacket

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 2 | DX002V***9KB |

5.0 (0.20) |

24.0 (16.0) |

1,800 (400) |

600 (130) |

5.0 (2.0) |

2.5 (1.0) |

||

| 4 | DX004V***9KB |

5.5 (0.22) |

29.0 (19.0) |

1,800 (400) |

600 (130) |

5.5 (2.2) |

2.8 (1.1) |

||

| 6 | DX006V***9KB |

6.0 (0.24) |

34.0 (23.0) |

1,800 (400) |

600 (130) |

6.0 (2.4) |

3.0 (1.2) |

||

| 8 | DX008V***9KB |

6.5 (0.26) |

39.0 (26.0) |

1,800 (400) |

600 (130) |

6.5 (2.6) |

3.3 (1.3) |

||

| 10 | DX010V***9KB |

6.5 (0.26) |

40.0 (27.0) |

2,100 (470) |

700 (160) |

6.5 (2.6) |

3.3 (1.3) |

||

| 12 | DX012V***9KB |

6.5 (0.26) |

43.0 (29.0) |

2,100 (470) |

700 (160) |

6.5 (2.6) |

3.3 (1.3) |

||

| 18 | DX018V***9KB |

7.5 (0.30) |

51.0 (34.0) |

2,400 (540) |

800 (180) |

7.5 (3.0) |

3.8 (1.5) |

||

| 24 | DX024V***9KB |

8.5 (0.33) |

63.0 (42.0) |

3,000 (670) |

1,000 (220) |

8.5 (3.3) |

4.3 (1.7) |

||

Click the symbol in the Part Number Configurator column above to a build specification sheet with specific part number information.

Instruction Sheets

Related Documents

More Broadcast Deployable Cables