You’ve heard of the Bro Code and seen all the different Bro Tips, right? Well, OCC is abiding by the Pro Code and we’d like to start sharing some of our Protips™ that everyone in the structured cabling business should know about!

Why choose OCC for fiber and copper product solutions?

Recently several OCC employees, customers and others were involved in a rather lengthy discussion on LinkedIn regarding the pros and cons of various structured cabling products among the different manufacturers. That conversation lead to our own internal discussions on why we are so proud to stand behind the products we offer, and ultimately, this blog post.

When looking for fiscally competitive products that also technically stack up in the industry, you don’t have to look any further than OCC. While industry professionals often tend to favor one manufacturer over another when discussing who has the best copper and fiber products out there (ourselves included!), OCC is confident in the products we sell and firmly believe that customers should let the tester do its job to tell them which products truly do perform the best.

OCC has a proven record of making quality products and offering similar 25 year product and performance warranties. In addition to being a leader in fiber optic cables, OCC has acquired numerous companies over the past few years that allow us to offer a wide variety of products including fiber optic cable and enterprise connectivity, as well as products for harsh environment applications; ultimately making us the ideal choice for a full solution provider within the industry.

With nearly 30 years of experience under our belts, OCC can offer customers reliable, high-quality products that not only outperform our competitors, but can also be offered to our customers at very competitive prices. Still asking why you should choose OCC for your fiber and copper needs? Let the tester do the work for you and see how OCC cable stacks up to all the rest!

How Fiber Optic Cable Sales Impacts the U.S. Economy

Optical Cable Corporation Wins Presidential “E” Award for Export Contributions

According to a recent release by the Bureau of Economic Analysis, the United States’ nominal GDP was estimated to be $16.8 trillion for 2013. Of that number, U.S. exports of goods and services accounted for $2.3 trillion, or nearly 14 percent, which is an all-time record.

Nationally, jobs supported by exports reached more than 11 million last year, up 1.6 million since 2009.

Every year, the Presidential “E” Award is presented to businesses that considerably contribute to exports, in recognition of the impact international sales has on the U.S. economy,

“OCC is extremely proud of this award,” Neil Wilkin, OCC President and CEO said. “It takes an entire team from engineers, to production employees, to both inside and outside sales associates to continually work together to support our export business. Dealing with the language, business and cultural issues of doing business internationally is sometimes a challenge, but it’s a challenge our team happily takes on to help OCC succeed.”

History of the Award

In 1961, the President’s “E” Award was created by Executive Order in an effort to recognize outstanding U.S. businesses that greatly contribute to international export.

President Kennedy revived the World War II “E” symbol of excellence to honor and provide recognition to America’s exporters. Thus, the “E” Award Program was established by Executive Order 10978 on December 5, 1961.

From Humble Beginnings to International Leader

Although OCC has sold products internationally from the very beginning, having shipped their first product overseas in 1986, a more strategic focus on the export market began in 1996. Since then, the company developed a targeted global approach, which has led to progressive growth through international sales. Today, export sales account for about 30 percent of the company’s total revenues, and since 2002, export sales have grown from less than $10 million to more than $22 million.

When asked his thoughts on receiving the “E” Award, OCC Vice President of International Sales & Global Marketing, Michael Newman said, “Achieving success internationally is all about taking a mindful approach to targeted markets; rather than trying to be everywhere at once. Start by narrowing in on global regions that make the most sense for your company, and then refine that strategy as you grow.”

Encouraged by this achievement, OCC will strive to serve more customers internationally, bringing the most reliable, rugged, and innovative cable products to the rest of the world.

To learn more about OCC’s products visit, https://www.occfiber.com/products.

Why the need for High Density Fiber Optic Enclosures?

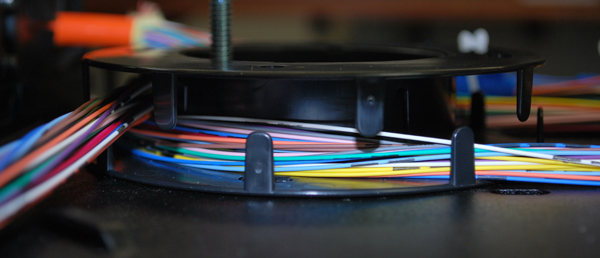

Increased demand for data to support streaming media and the increased usage of mobile broadband communications has resulted in dramatic advances in network switching infrastructure over the past 10 years. Furthermore, this demand is predicted to continue at a record pace. Technology development has seen two clear trends.

- The transition from copper to fiber as the defacto standard for high performance data communications has become evident.

- The number of fibers used to support emerging standards, such as 100GBit/s Ethernet, for the individual connection has increased.

Thus, the need for higher density fiber connectivity is certainly innate. Currently network switching products are available with port line cards that use more than 1,000 OM3/OM4 fibers per chassis switch for 10G duplex fiber applications. Future 40/100Gb switches are projected to use more than 4,000 fibers per chassis where parallel optics is used. These high fiber count requirements demand high-density cable and hardware solutions that will reduce the overall footprint and simplify cable management and connections to the electronics.

OCC’s new RTC/RTS-HD Series product allows customers to migrate from a standard RTC/RTS 2U fiber enclosure that will house 3 adapter panels for a maximum of 72 LC connectors to our new RTC\RTS-HD enclosures that will hold 4 adapter panels in a 1U space allowing a maximum of 96 LC connectors! This gives users 33% (or 24 more) more LC connections in a 1U enclosure versus a 2U enclosure.

The Procyon product allows for even more density by utilizing our MPO/MTP to LC cassette module for maximum port density. Procyon can deploy 144 LC fibers in a 1U footprint. And the Procyon 1U enclosures can be mounted vertically so you can match every blade in the switch to each enclosure.

With the rise in demand for higher bandwidth and faster download speeds, OCC’s high-density options were designed to keep pace with these requirements. In addition, both of these unique product lines offer installers easy terminations, and performance-driven connectivity. Couple that with OCC’s proven fiber optic cable, in particular our HD and HC cables, customers can expect an exceptional solution to fit their high-density needs.

Our new RTS and RTC fiber enclosure updates, and what they mean for you.

OCC recently debuted our newly redesigned fiber termination enclosures with a fresh look and features that make them easier to work with. The updated enclosures allow for easier terminations, greater capacity, and new ways to manage cable within the enclosure.

Designed with features that benefit both the end user and the installer, OCC’s enclosures feature the following:

- Fixed (RTC) and sliding (RTS) versions

- 1RU, 2RU, and 4RU configurations

- Sliding (RTS) version can be accessed from the front or back of the enclosure

- The RTS shelf can be removed entirely

- Enclosures accept OCC standard 600 series adapter plates

- RTC-HD and RTS-HD enclosures accept new HD adapter plates

- New modular strain relief brackets reduce fiber stress and provides

- Fiber hoops are stackable and allow for segregation of fiber cables

- Fiber retention teeth on the hoops retain the fiber within the hoop

- Slam latches on the front and rear of the enclosures

- Transparent cover for inspection of ports and defined labeling field for TIA 606A compliance

- Hardware for 19” or 23” rack mounting

- Numerous internal locations to secure slack cable

The RTC and RTS enclosures will be on display at the 2014 BICSI Winter Conference and Exhibition in Orlando, FL in February.