Passive Optical LAN (POL) is a new way to structure a telecommunications network, replacing traditional structured cabling, which consisted of multiple levels of switch and router aggregation.

In the traditional model, data was transmitted and dispersed to the desktop through layers of switches, cables and routers. Expanding structured cabling over long distances requires installation of additional switches and routers to carry the signal. This means lots of expensive cable, support infrastructure and labor time.

POL is a more cost effective and energy efficient alternative. POL uses a different architecture with single-mode fiber extended closer to the user and electronic devices that flatten the Local Area Network, eliminating distance constraints and reducing the quantity of cable to the workstations.

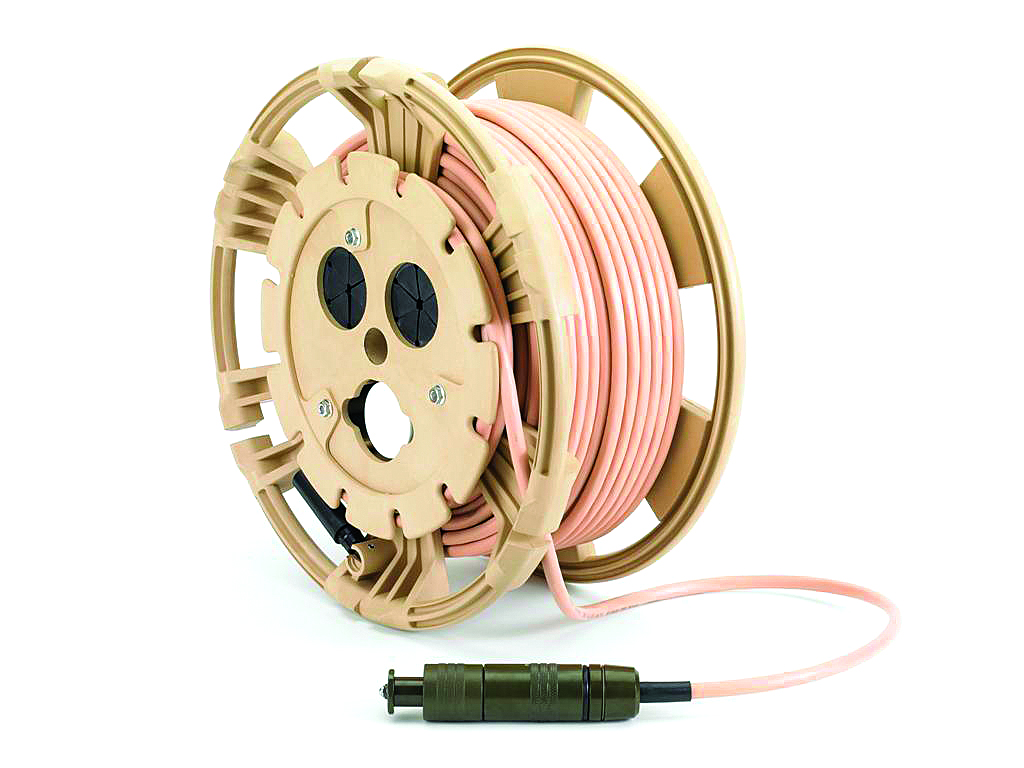

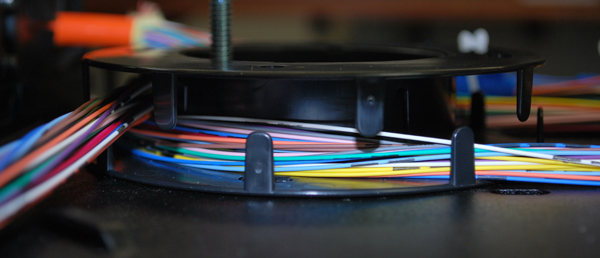

A POL consists of an optical line terminal (OLT), an optical splitter, and optical network terminals (ONTs) to transmit voice. An optical splitter splits downstream signals and combines upstream signals to and from the connected devices, all on a single strand of singlemode fiber. Additionally, since the ONTs can support multiple devices, Passive Optical LANs require less cable (and the labor to install it) to support the network.

Benefits of POL:

- Cost savings

- Energy efficient

- Easy install and maintain

- Eliminates need for telecommunications rooms

- Simplifies network moves, adds and changes

- Increased security

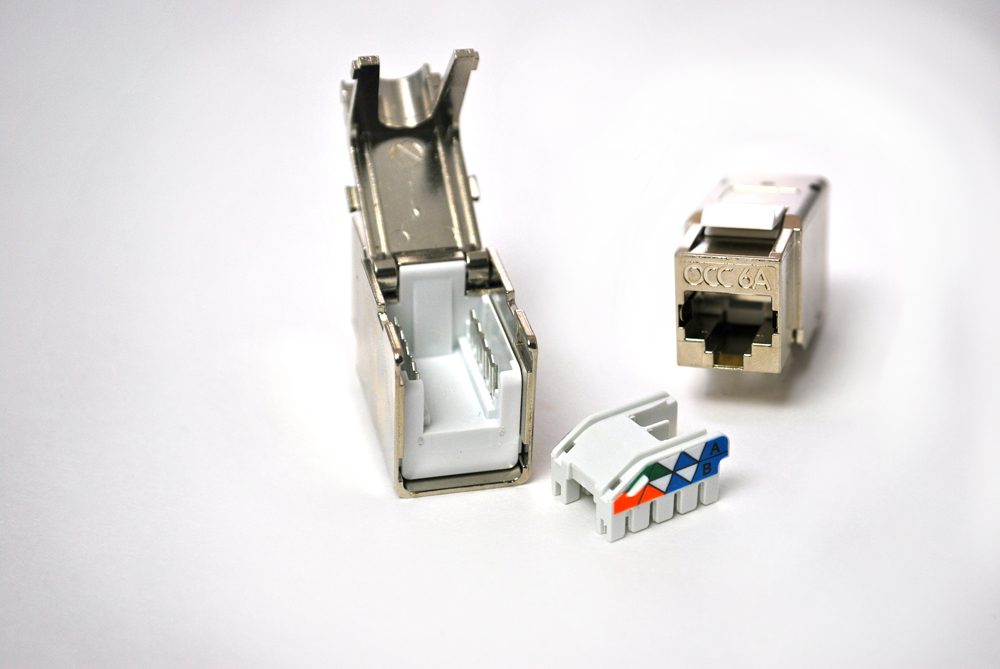

OCC has always been known for its tough components and rest assured, the POL Solutions are no different. OCC’s standard multi-fiber and simplex cables provide noteworthy mechanical and environmental performance with greater pull strength, greater impact and crush resistance and bend insensitive fibers. The POL connectivity components are the most resilient on the market

Specifically designed components for the POL easily integrate with all OCC structured cabling fiber optic components providing for a simple installation. OCC offers the best cabling in the industry coupled with service and tailored options, making your choice for a Passive Optical LAN simpler.

demanding applications including:

demanding applications including: