G-Series Subgrouping – Riser Rated Cables

Installation zone RECOMMENDATION1

1

1

1

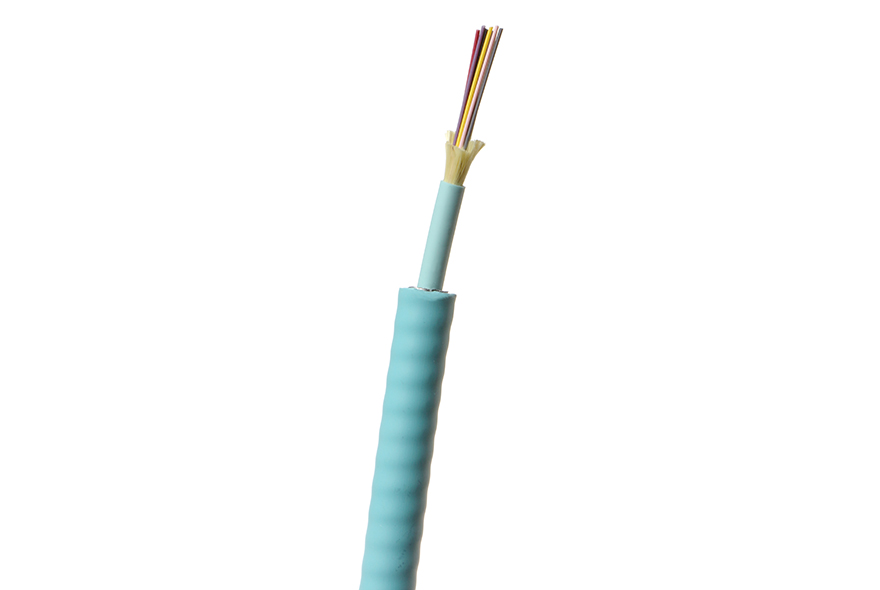

- Indoor/Outdoor tight-buffered design allows cables to be installed in intra-building backbone and inter-building campus locations without costly transitions between cable types

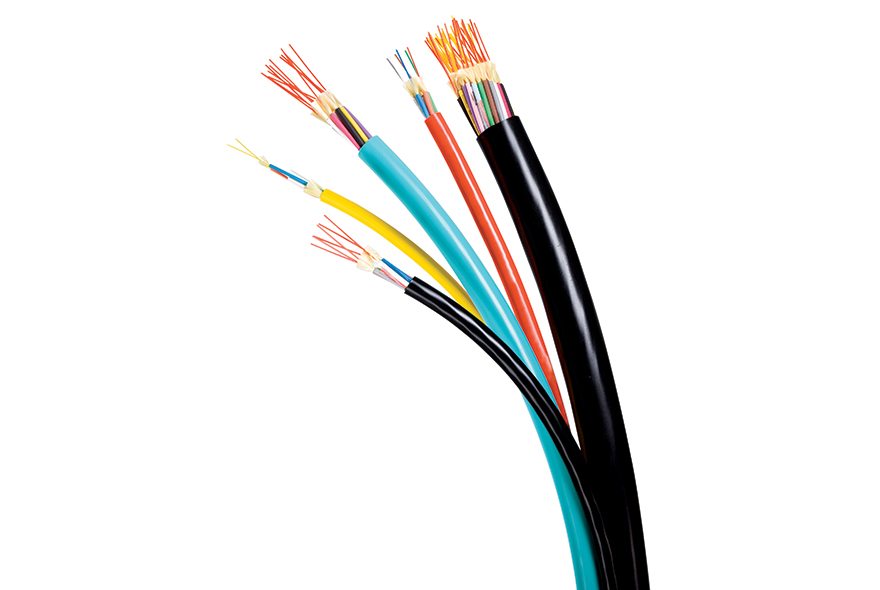

- Design allows multifiber subcables to be routed to multiple locations, such as wiring racks and closets

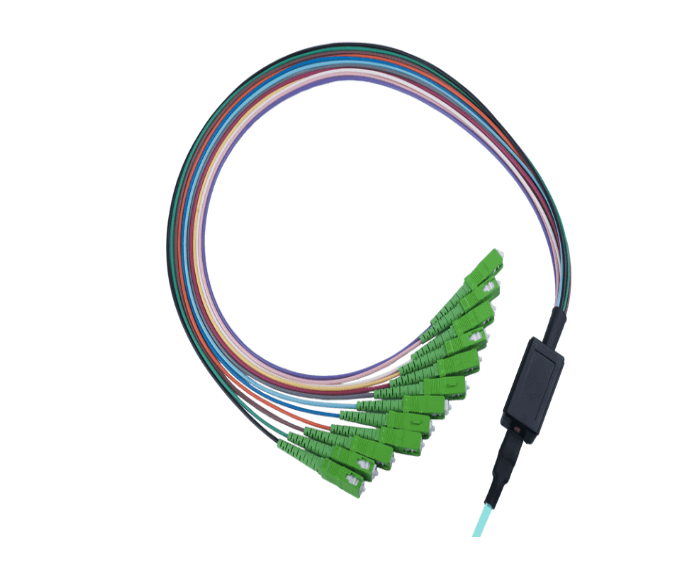

- 900μm buffer eliminates the need for costly and time-consuming installation of fanout kits or pigtail splices, because connectors terminate directly to the fiber

- No need to splice outdoor cable to indoor cable at building entrance

- High crush resistance may eliminate the need for innerduct

Applications

- Fiber Optic tray Cable: Suitable for use in cable trays

- Indoor/Outdoor tight-buffered design allows cables to be installed in intra-building backbone and inter-building campus locations without costly transitions between cable types

- Design allows multifiber subcables to be routed to multiple locations such as wiring racks and closets

COST SAVINGS

- 900 µm buffer eliminates the need for costly and time-consuming installation of fanout kits or pigtail splices because connectors terminate directly to the fiber

- No need to splice outdoor cable to indoor cable at building entrance

- High crush resistance may eliminate the need for innerduct

Features

- High performance components and construction

- UL Listed in accordance with NEC sections 770.179(b) for use in vertical runs in building riser shafts or from floor to floor

- Cable materials are indoor/outdoor: UV, water and fungus resistant

- Wide operating temperature range of -40°C to +85°C

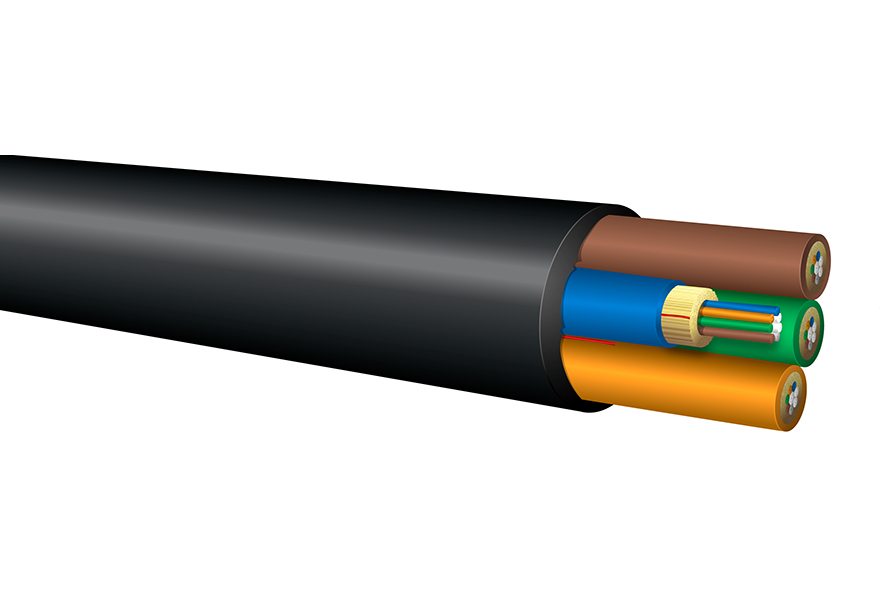

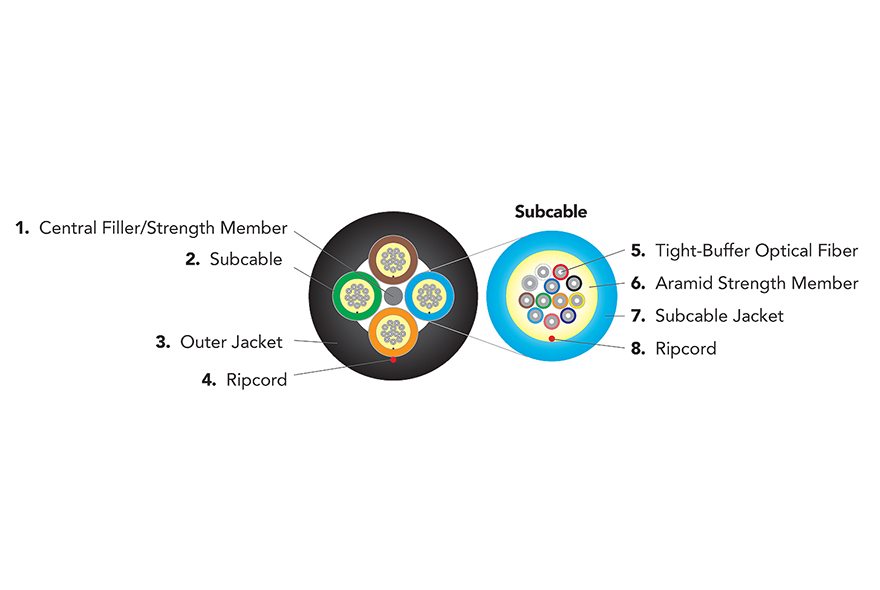

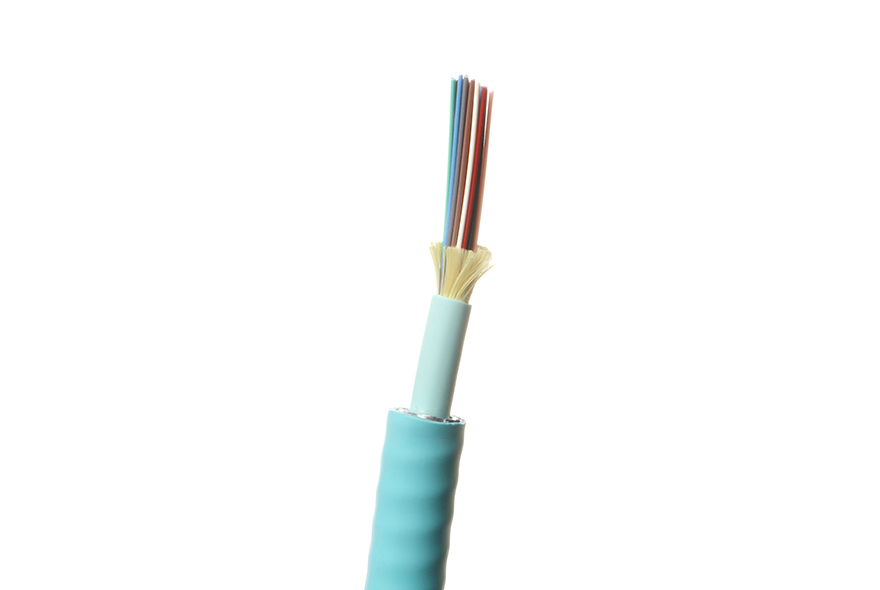

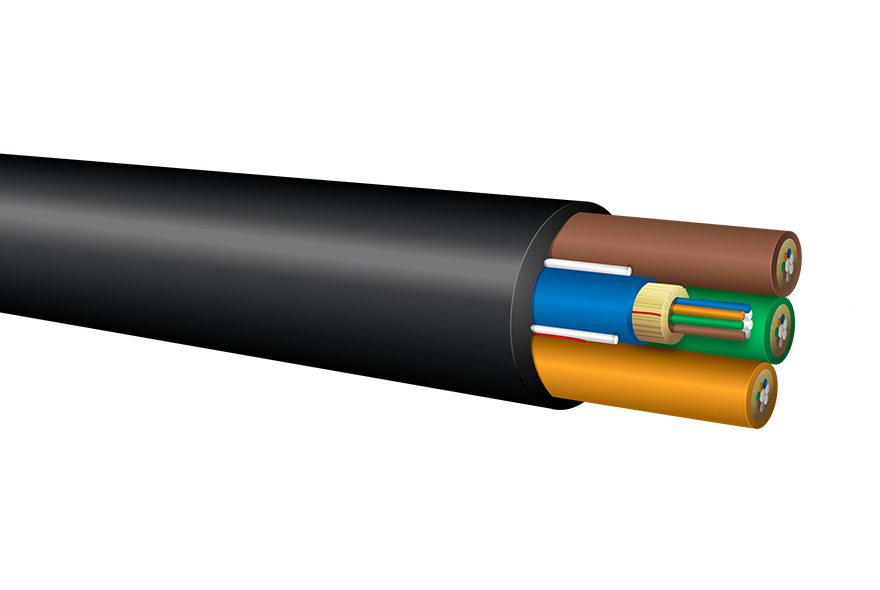

- Helically stranded core for greater flexibility and mechanical protection of the optical fibers

- Core-Locked® outer jacket surrounds the subcables for excellent crush resistance, survivability and use in long vertical installations

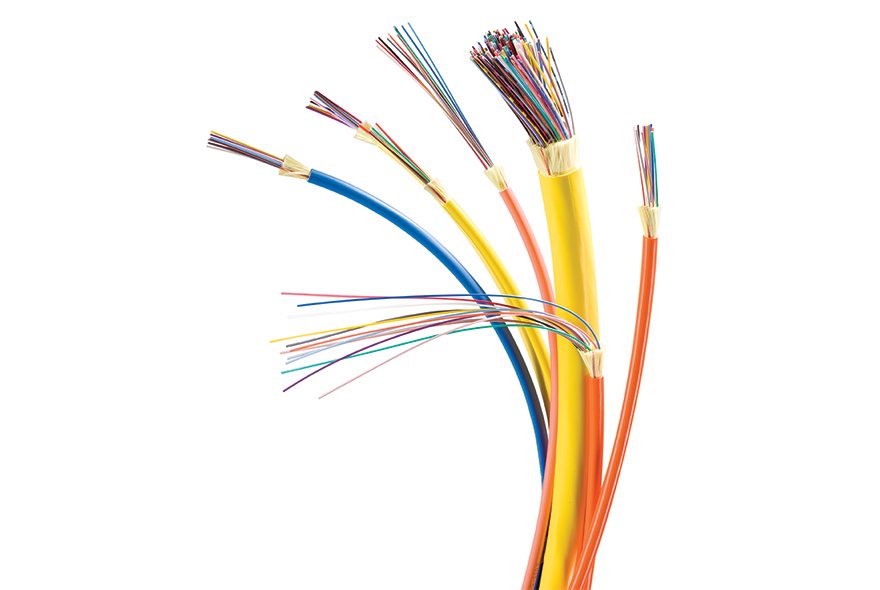

- Multifiber color-coded subcables, each similar to the D-Series Distribution cable, are easy to identify for improved cable management during installation

- Subcabling cable design permits mid-span access

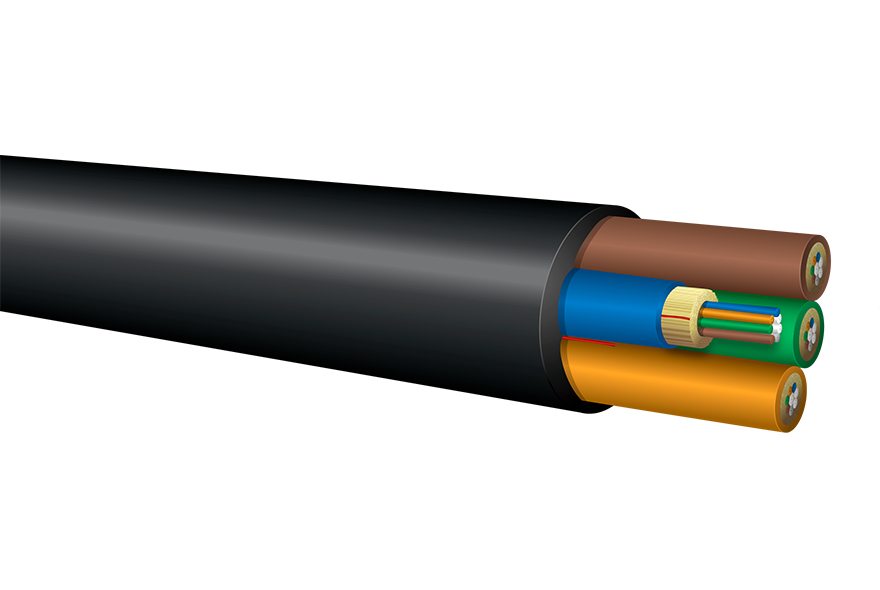

- Best design for multimode and single-mode fiber hybrid cables

- Ideal for direct pulling with wire mesh grips

- Available with 6-fiber (4.5mm) or 12-fiber (5.5mm) subgroups

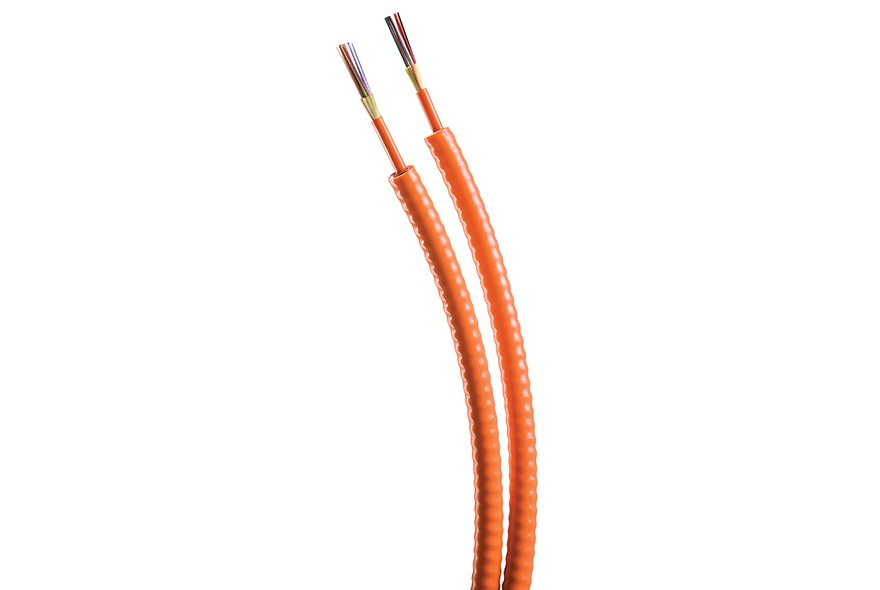

- Interlocking armor can be applied to cables as an alternative to conduit installation

Characteristics

| Characteristic | 6 Fiber Subunits | 12 Fiber Subunits |

|---|---|---|

| Operating Temp | -40°C to +85°C | -40°C to +85°C |

| Storage Temp | -55°C to +85°C | -55°C to +85°C |

| Install Temp | -10°C to +60°C | -10°C to +60°C |

| Flame Retardancy | UL Listed Type OFNR (UL 1666) and FT4 (CSA C22.2 No. 232) | UL Listed Type OFNR (UL 1666) and FT4 (CSA C22.2 No. 232) |

| Crush Resist | 2100 N/cm | 2100 N/cm |

| Impact Resist | 1500 impacts | 1500 impacts |

| Flex Resist | 2000 cycles | 2000 cycles |

| Jacket Type | D | D |

Standards

Optical Cable Corporation's Indoor/Outdoor tight-buffered fiber optic cables meet the functional requirements of the following standards:

- UL 1651

- UL 1666

- GR-409-CORE

- ICEA-S-104-696

- ICEA-S-83-596

- TIA-568

- TIA-598

Specifications

6-Fiber (4.5mm) Subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 12 | GB012D***9*R |

14.6 (0.57) |

207.0 (139.0) |

3,800 (850) |

1,200 (270) |

21.9 (8.6) |

14.6 (5.7) |

||

| 18 | GB018D***9*R |

14.6 (0.57) |

208.0 (140.0) |

4,700 (1,060) |

1,800 (400) |

21.9 (8.6) |

14.6 (5.7) |

||

| 24 | GB024D***9*R |

14.6 (0.57) |

209.0 (140.0) |

5,600 (1,260) |

1,800 (400) |

21.9 (8.6) |

14.6 (5.7) |

||

| 30 | GB030D***9*R |

15.6 (0.61) |

240.0 (161.0) |

7,500 (1,690) |

2,400 (540) |

23.4 (9.2) |

15.6 (6.1) |

||

| 36 | GB036D***9*R |

16.9 (0.67) |

282.0 (189.0) |

8,900 (2,000) |

2,850 (640) |

25.4 (10.0) |

16.9 (6.7) |

||

12-Fiber (5.5mm) Subcables

| Tensile Load | Minimum Bend Radius | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Count | Part Number | Part Number Configurator | Diameter mm (in) |

Weight kg/km (lbs/1,000ft) |

Installation N (lbs) |

Operation N (lbs) |

Installation cm (in) |

Longer Term cm (in) |

|

| 24 | GX024D***9*R |

16.6 (0.65) |

259.0 (174.0) |

4,600 (1,030) |

1,500 (340) |

24.9 (9.8) |

16.6 (6.5) |

||

| 36 | GX036D***9*R |

16.6 (0.65) |

258.0 (173.0) |

5,900 (1,330) |

1,050 (440) |

24.9 (9.8) |

16.6 (6.5) |

||

| 48 | GX048D***9*R |

16.6 (0.65) |

257.0 (173.0) |

7,200 (1,620) |

2,400 (540) |

24.9 (9.8) |

16.6 (6.5) |

||

| 60 | GX060D***9*R |

18.4 (0.72) |

308.0 (207.0) |

9,500 (2,140) |

3,150 (710) |

27.6 (10.9) |

18.4 (7.2) |

||

| 72 | GX072D***9*R |

20.1 (0.79) |

364.0 (245.0) |

11,300 (2,540) |

3,750 (840) |

30.2 (11.9) |

20.1 (7.9) |

||

| 84 | GX084D***9*R |

21.8 (0.86) |

425.0 (286.0) |

13,100 (2,950) |

4,350 (980) |

32.7 (12.9) |

21.8 (8.6) |

||

| 96 | GX096D***9*R |

23.6 (0.93) |

495.0 (333.0) |

14,900 (3,350) |

4,950 (1,110) |

35.4 (13.9) |

23.6 (9.3) |

||

| 108 | GX108D***9*R |

25.7 (1.01) |

587.0 (394.0) |

18,200 (4,090) |

6,000 (1,350) |

38.6 (15.2) |

25.7 (10.1) |

||

| 120 | GX120D***9*R |

27.7 (1.09) |

684.0 (460.0) |

19,500 (4,380) |

6,450 (1,450) |

41.6 (16.4) |

27.7 (10.9) |

||

| 132 | GX132D***9*R |

28.1 (1.11) |

646.0 (434.0) |

20,800 (4,680) |

6,900 (1,550) |

42.2 (16.6) |

28.1 (11.1) |

||

| 144 | GX144D***9*R |

28.1 (1.11) |

645.0 (433.0) |

22,100 (4,970) |

7,350 (1,650) |

42.2 (16.6) |

28.1 (11.1) |

||

Instruction Sheets

Related Documents

Please Login Here to access additional documents.

More Indoor/Outdoor Cables